SILENCIONS TECHNOLOGY

s|ANC|

Active noise reduction based on AI

Silencions s|ANC| is a new generation active noise cancellation (ANC) system. Where traditional passive noise reduction methods prove insufficient, our system actively neutralises noise at its source.

Using machine learning (ML), s|ANC| accurately predicts and suppresses persistent low frequencies within milliseconds. It is an effective solution designed to work in demanding environmental conditions.

HOW DOES THE SILENCIONS s|ANC| SYSTEM WORK?

The power of the ANC

The solution is the result of the work of an interdisciplinary research team, integrating knowledge in the fields of engineering acoustics, advanced algorithms and mechatronics. The implementation of machine learning and artificial intelligence algorithms defines the unique nature of the solution, providing key technological advantages:

- integration of advanced machine learning technologies in the signal processing process,

- high attenuation efficiency, also covering higher frequency ranges,

- robust mechanical design adapted to operation in harsh conditions.

SOFTWARE ARCHITECTURE AND CONTROL ALGORITHMS s|ANC|

s|ANC| SOFTWARE

The Silencions s|ANC| system uses machine learning algorithms to predict sound waves. A key engineering achievement is the drastic reduction of signal delay (latency) by the analogue-to-digital processing system. Thanks to the optimisation of the hardware and software layers, the initial delay of 200 ms has been reduced to a few milliseconds.

Implementation of FxLMS adaptive filters and neural networks

The research work included the development of an algorithm for collecting training data sets. The system is based on FxLMS adaptive filters and operates in two modes: learning and active ANC.

The collected data can be used to optimise the system in many ways. One of them is to use the data to predict the weights of adaptive filters by a neural network. The application of this solution allows for a significant reduction in the convergence time of the system in the event of sudden changes in the acoustic signal characteristics.

design and prototyping

s|ANC| HARDWARE

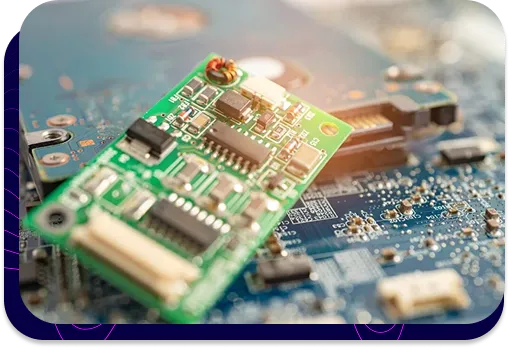

The unique design of the enclosure was tailored to the requirements of a dedicated PCB (Fig. 1), which necessitated precise adaptation of the structure to specific operational requirements.

During the research and development phase, rapid prototyping methodology was used to produce prototypes of components, based on advanced additive technologies, in particular LPBF metal 3D printing.

The final design successfully passed certification tests, confirming compliance with the requirements of the following standards:

- IP34 – degree of internal protection (against solid objects and water splashes),

- IK06 – degree of resistance to mechanical impact.

The quality is confirmed by the certificate of conformity No. LT/606.3/2023.

Test setup and experimental results

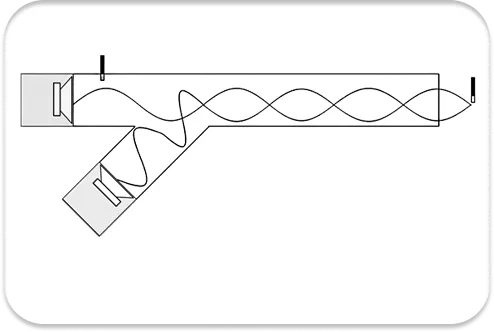

In order to verify the functionality of the system and the developed algorithms, a prototype research environment in the form of a ventilation duct was constructed (Fig. 3). This made it possible to conduct research under controlled conditions, with a precisely defined sound wave propagation path.

Two broadband sound sources (frequency response 38 Hz–18 kHz) in dedicated enclosures were installed inside the ventilation duct. The first loudspeaker served as a noise source simulator, while the second acted as an active noise cancellation (ANC) signal emitter.

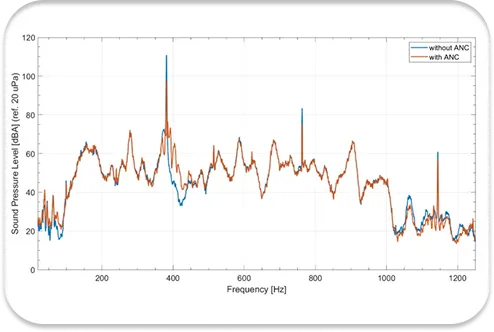

Validation tests of the developed solution were carried out in a duct application. Fig. 4 shows the amplitude-frequency characteristics (in the range up to 1250 Hz) measured at the duct outlet, in close proximity to the error sensor. The graph compares the effectiveness of the system in passive mode (without active ANC – blue line) and active mode (with active ANC – red line).

Analysis of the results indicates a significant reduction in the sound pressure level (SPL) of the measured signal after activation of the S|ANC| system.

- For the first dominant frequency, a reduction of approximately 13.2 dB was achieved.

- For the second dominant frequency, a reduction was approximately 8 dB.

Intellectual property protection

Silencions Intelectual Property

As part of the strategy to protect the results of research and development work, a patent application has been filed. The application covers two examples of the innovative technology, which have been described in detail and documented with supporting technical diagrams. The procedure to obtain full legal protection for the developed technology is ongoing.

Consultation and partnership in R&D projects

Are you looking for advanced solutions in active noise reduction? Our team is ready to take on new challenges.

We specialise in diagnosing acoustic problems, neutralising them at source and creating adaptations for special tasks.

We are available on working days from 9:00 to 17:00.

Phone: +48 736 424 903

Email: contact@silencions.com

You can also use the contact form: